Design Capability

Design expertise comes from being in the

'trenches' of real-world packaging problems and solutions. Technology

packaging requires many disciplines to achieve the proper form, function

and reliability for the application. Complex devices require unique

solutions for packaging while minimizing cost and development time.

Design considerations include an array of choices for materials,

processes and qualification that can be simplified with the help of our

experience and tools. Design tools are available for literally all

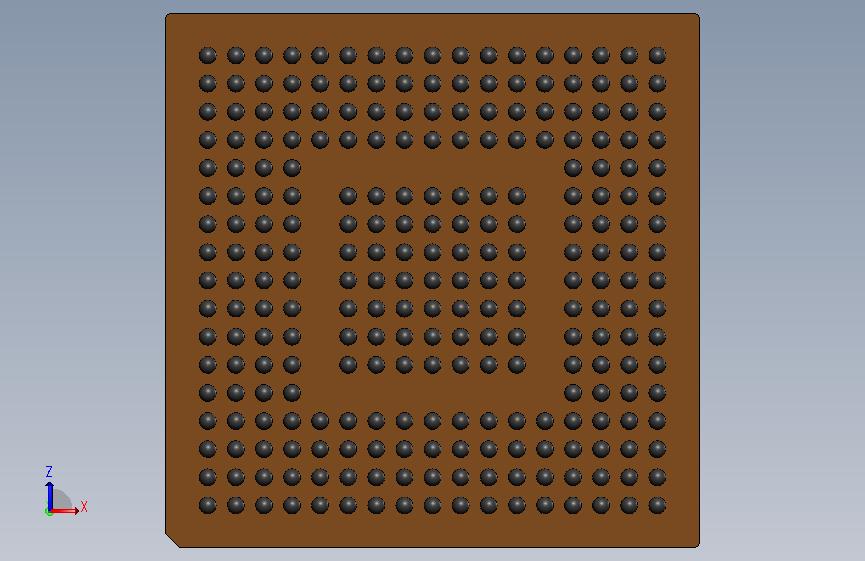

package types including leadframe, QFN, BGA, organic and hermetics.

Auto-layout and wire bond routing in 3D is available for single and

multi- or stacked-chip designs. Full 3D modeling and simulation,

parameter extraction and thermo-mechanical analysis support during the

design phase.

End-to End Design Flow

Feasibility

Initially, data is collected on the device, application environment,

performance requirements and qualification level. Desired

characteristics such as cost, geometry and schedule are captured along

with the customers vision of the final product. When a clear

understanding of the entire application is gained, design options are

discussed with suggestions on materials, form-factor, assembly options,

suppliers, cost and timeline. Short and long-term goals are stated and

technical milestones are defined.

0th Order Design

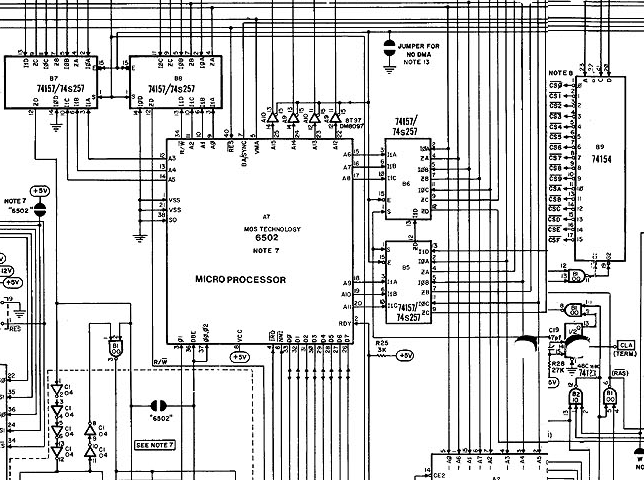

With the information provided by the customer, design options are

presented. Input includes schematics, netlists, chip xy plots and

dimensions and other pertinent data. From these options, the best fit for the product is

determined. Basic performance is estimated for the assembly and problem

areas are defined. Critical performance parameters are defined and

options for modeling and characterization are discussed. Assembly

processes and materials are recommended. After reviewing the design

options the customer chooses a design path with the desired

characteristics and acceptable tradeoffs. The extent of performance

characterization and modeling is agreed upon and the initial design

decisions are documented.

1st Order Design

In this phase of the project the design is further developed and the

first producible design is generated in concert with customer

engineering. Models, characterizations and reliability predictions are

generated and the results are reviewed and approved. Materials suppliers

and assembly services are selected based on the customer needs keeping

transition to production in mind. Initial process parameters are

defined. Cost models are developed and target costs for prototype and

production are developed. RFQ are generated and prototype houses are

reviewed for capability and history. Production partners are reviewed.

Prototype Phase

Once the assembly provider is selected, quotes are in and budgets are

established and approved, work begins with prototype assembly. Lot sizes

are determined based on reliability and test requirements. All bond

diagrams, routing, package mechanical drawings and assembly

specifications required by the assembly supplier are generated and

reviewed for accuracy and completeness. Materials are ordered and and

timelines are set for first articles.

Test and Reliability Phase

When the first articles are complete, the lots are broken out into the

reliability and test operations. Minimum sample quantities are tested to

determine performance characteristics and reliability behavior. Based on

the results of these tests, any problem areas are approached and

solutions are discussed. At some point during the reliability tests the

risk for failure is assessed and plans for the final design can be

completed.

Final Design Phase

Once all of the performance, cost, reliability and supplier issues are

fixed the final design review is held. Upon approval detailed first

production quantities and expected yield are determined and refined cost

models are presented. All processes are documented and signed off.

Package drawings, customer part numbers, model and test results and all

other required documentation and qualification specifications are

checked and approved. During this time, selected production partners are

audited and on-site inspections are carried out where needed. The

production partner is selected.

Production Phase

The transfer team personnel have been selected and production dates and

quantities are set. The engineering resources, documentation package,

supply chains and production schedules are fixed. The transition team

works at the production site to transfer the process, observe working

practices, collect failure data and samples for analysis, and approve

the production process at the selected facility

Design Tools

Package Science Services has a wide array of tools for design

Thermal Characterization and

Modeling

Thermal

modeling tools

Complete thermal and

electrical characterization labs.

_100-QFP-0041-R0.png)